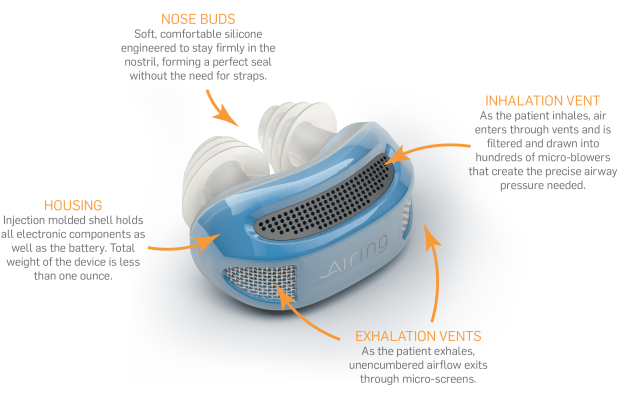

The Body and the Nosebuds are visible while the Electronics, Pressure Sensors, Micro-blowers, and Battery are housed within the body of the device. We have been working on all of these components in parallel and would like to take a moment to give you a status report on each of them.

Body- The design of the housing or body of the Airing device is recognizable throughout the world. The attractive design, made of injection-molded plastic, may be modified slightly to accommodate minor changes in the configuration of the battery and other internal components.

Nosebuds- Also known as the "nasal interface," the nosebuds have been designed, built, and tested while integrated onto a test body. This test body allowed for normal breathing straight through the unit and allowed us to simulate the size and weight of the proposed completed device with various nose bud designs. Molded from a soft and pliable silicon rubber material, the shape of the nose buds provides a gentle and flexible seal with minimum exposure to the surface of the nasal pathways. Furthermore, our tests have determined that the nose buds form a seal within the nose that maintains the full range of treatment pressures. It is comfortable enough to allow the user to fall and stay asleep while wearing it and it remains in place through the night.

Continued adjustments in the shape and materials of the nose buds have further improved retention and comfort. The amount of material within the nose has been reduced as the shape evolves. We will continue to improve the fit and feel of the nasal interface, but our current design will allow us to perform effective testing of the micro-blower component prototypes.

Electronics- Right now the electronic circuitry resides outside the body of the device. This enables us to make adjustments easily as needed. Once the “circuits” are finalized, they will be miniaturized to fit inside the housing. We are fortunate to have a world-class multi-billion dollar company that has extensive experience with the production of just such electronics to assist with this process.

Pressure Sensor- As we have described in our previous blog, Airing’s micro-CPAP device wouldn’t work without a micro pressure sensor. The micro pressure sensor has two very important functions. First, it is an integral part of the feedback loop that ensures that the micro-blowers are delivering the pressure needed to maintain the treatment level prescribed by your physician. Second, the pressure sensor collects data about your use of the device, which can be used to prove the compliance for insurance reimbursement purposes.

Micro-blowers- Micro-blowers are the heart of Airing device. And we’ve got them beating! All but one of the components within the micro-blower are working as designed. We’ve pinpointed the problem. We are confident that with a few more tweaks to this one tiny part, the micro-blower it will work as designed. We are close but not quite there yet. A recent blog provides further discussion about the status of the micro-blowers.

Battery- Several key factors were considered in designing the power source for the Airing device: power per weight and volume, ease of manufacture, cost, and environmental impact. The Zinc-air battery was the clear winner in all categories.

The Zinc-air battery provides about ten times more stored energy in the same space as the same-sized Lithium-ion battery. In fact, a rechargeable Lithium-ion battery that could last through the night would make the device too heavy for convenient and comfortable use, our primary concern.

Zinc-air is a proven and inexpensive technology. It is the same type of battery that is used in hearing aids and it was used for years in Polaroid film packages. Furthermore, it can be manufactured cost effectively using the roll to roll process. And unlike some of the other caustic, more corrosive, battery technologies, the Zinc-air is environmentally benign — basically a common metal and soap. We have been discussing, with battery manufacturers, the power specifications needed to operate the micro-blowers (hundreds of them; each one pumping thousands of times per second). Not only are such battery specifications readily achievable, but also at our estimated cost.

Our excitement is building. Things are really coming together. We just wanted to take a moment to give a broader perspective on the good progress we are making on the various components of Airing. Thank you to all our supporters and followers who have been with us on this journey. We are anxious to be able to move on to the next phase in the development of the Airing micro-CPAP device.

Stephen Marsh and the Airing Team

JOIN OUR "KEEP ME POSTED" LIST!