Hello, Airing Community!

We have an early gift for this holiday season. We are beyond excited to share that the prototype of the micro pressure sensor, one of the key components of the Airing micro-CPAP device, is complete! So, here we are with another key component: the micro pressure sensor. It has been prototyped and tested, and it works!!

What is Pressure Sensor you ask? It is a small element that measures the pressure of the air. According to Dr. Adriano Pittarelli, Senior Product Manager at Sensortechnics:

“Today’s (CPAP) machines incorporate a high precision pressure sensor, which constantly compares the actual value of the pressure with the set value specified for the therapy…Pressure stability is a fundamental mark of quality and an important comparison parameter for these controlled CPAP machines.”

Our micro pressure sensor has two very important functions. First of all, Airing’s micro-CPAP device wouldn’t work without it. It is an integral part of the feedback loop that ensures that the micro-blowers are delivering the pressure needed to maintain the setting prescribed by your physician. In addition, the pressure sensor collects data about your use of the device, which can be used to prove compliance for insurance reimbursement purposes. This usage data can also be used to meet compliance regulations established by transportation authorities.

Pressure sensor element

In our “Honey, I Shrunk the CPAP” blog; we described how the micro-blowers are a class of device referred to as micro-electro-mechanical systems, or MEMS. We can now tell you that there are other MEMS structures inside of the Airing micro-CPAP device: micro-pressure sensors. With every breath you take, they’ll be providing the feedback to allow the system to deliver and maintain your treatment pressure level.

It turns out that the MEMS technology we use for building micro-blowers can be used, in a different configuration, to sense pressure. With micro-blowers, we use membranes to push air. With micro-pressure sensors, we use the air to push membranes. Very similar indeed!

Using the same types of materials and processing as the micro-blowers, we can fabricate these micro-pressure sensors cost effectively and incorporate multiple devices for additional sensitivity and safety. This type of manufacturing allows for an unprecedented level of integration between the micro-blowers that push the air and the micro-pressure sensors that measure it.

From the beginning, we have anticipated the integration of the micro-pressure sensors into the Airing micro-CPAP device. However, our initial and priority focus was on the micro-blowers. But, as we have described, it is important in technology development to be working on multiple components in parallel; and we have been.

Therefore, we are using what we learn during the prototyping of the micro-blowers to fabricate our design of the micro-pressure sensor. These proof of concept prototype sensors were constructed for bench testing where we could verify their operation and characteristics.

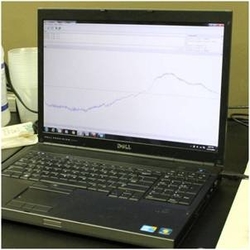

Pressure data collected by sensor

Once they were assembled, we connected them to a test rig that could apply various pressures throughout the active range of CPAP therapy pressures. We looked for accuracy, repeatability, range and dynamic response. We are pleased to announce that they work. And, they work very well!

The Airing micro-CPAP device is an amazing innovation and is made up of a number of components that are based on inventions that have to be developed and proven. The completion of this prototype component brings us one step closer to completing the prototype of the micro-blowers which are quite similar to the micro pressure sensors but with more moving parts.

As we have described before, development is not a linear process. It has the characteristic of moving slowly in the beginning, but then it picks up and (usually) moves much faster in the end. While we are primarily focused on the micro-blowers, these micro-pressure sensors are a good example of how we are working in parallel to reduce the overall product development time frame.

We are happy to report in this blog that one more component, the micro-pressure sensor, has been prototyped and tested. We want to thank our Airing community for their support and enthusiasm. Your contributions continue to help us fund our development and to increase our pace. We will keep you updated and share our progress as often as we can.

- Stephen Marsh and The Airing Team