REMEMBER MEMS?

Back in November, we wrote a blog post to give some background information on the type of breakthrough technology we are developing for Airing. In it, we introduced you to MEMS, a type of micro-scale technology that is invisible to the naked eye, yet controls the advanced functioning of everything from cars to cell phones to implantable heart sensors. This technology lies at the core of what allows Airing to be free of the bulk, mask, straps, and hoses of traditional CPAP machines. In that same post, we also introduced the SEM, or Scanning Electron Microscope, a powerful tool we use for examining the micro-structures we are creating with maximum detail and precision.

In the time since posting that article, we have been busy constructing the prototype of our micro-blower body; carefully refining, testing, and analyzing using a SEM to get a final form that matches our unique design.

OUR (TINY) TECHNOLOGY

As you may have seen in our technology video, each of Airing’s displacement pumps will be operated with opposing electrostatic charges in order to repeatedly expand and collapse, pushing a constant stream of air up into the nose (think of an old-fashioned fireplace bellows). Pumping thousands of times a second and assembled in parallel within the device, these units will work together to achieve the flow rate required to maintain positive airway pressure.

A diagram of the technology behind Airing’s revolutionary approach to CPAP therapy.

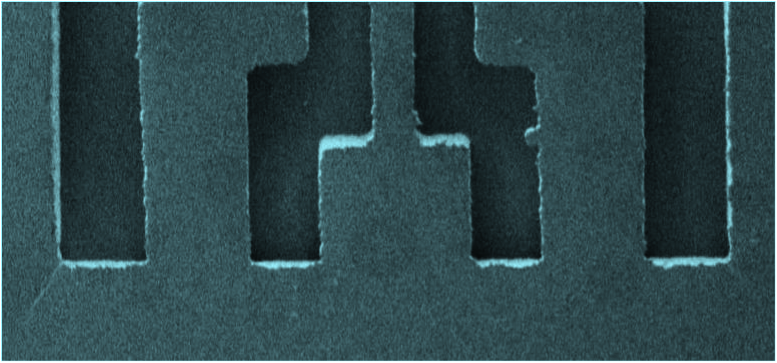

The above diagram gives a clear picture of how the micro-blowers will function. But we want to give you a much closer look. The image below is a detailed close-up of a section of our micro-blower prototype, taken with a SEM. The features of the micro-blowers are measured in one millionth of a meter (one micron). For reference, 100 microns is about the width of a strand of human hair.

Micron scale micro-formed air channels of basic micro-blower.

Despite its size, air will be sucked into the grooved channels of this structure with the help of the electrostatic charge and fill each expanding displacement pump. Then, with an opposite charge, the pump body will collapse and the air will be pushed out to the other side.

BETWEEN THE SHEETS

In addition to constructing Airing’s basic pump body, we have identified a material that has proven to be among the safest, strongest, most elastic, and most cost-effective choice to use for our micro-blower components. We have begun patterning this material in sheets, the result of which can be seen in the photo below.

Sheet of latest version micro-blower component.

We are fabricating the components of our micro-blowers in large numbers in order to streamline the evaluation and analysis process. By patterning our pump body prototypes in large batches, we can move through this stage with improved efficiency. All of this patterning will serve to ensure that the material we have identified is able to reliably conduct electricity and provide proper structure to each layer of the micro-blowers.

In the coming weeks, we will continue to construct and evaluate our pump-body prototype and patterning in preparation for assembly and testing.

Stay tuned for more updates!

THE AIRING EQUITY CROWDFUNDING CAMPAIGN IS LIVE ON WEFUNDER.COM

CLICK TO INVEST TODAY!